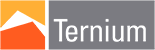

Conventional Bag Filter (High Pressure)

The conventional bag filter (high pressure) is used to filter various particulate materials from industrial process gases, whose forced flow through exhaust provides a continuous gas filtration operation through the bags.

CRANFOS High-Pressure Bag Filter: Durable, Efficient, Auto-Cleaning

The conventional bag filter (high pressure) is used to filter various particulate materials from industrial process gases, whose forced flow through exhaust provides a continuous gas filtration operation through the bags.

The bags, vital items for the proper functioning and efficiency of the equipment, have characteristics appropriate for each type of process, where variables such as temperature, gas composition and emission limit make the choice of the type of bag very important, since these variables will also increase or decrease the total pressure loss for dimensioning and specification of the fan that will exhaust the gases through ducts and hoods to the filter.

With advanced technologies, the bags used in our equipment are manufactured with the best materials on the market and are highly resistant. They are manufactured according to the project, which allows us to use specific diameters and different lengths. And thanks to advanced manufacturing processes, their cost is not an impediment to making our filters financially attractive.

The same meaning can be used to describe cages, venturis and other fastening items, which are designed and suitable for each type of industrial process.

As the gas passes through the bags, the particulate matter is retained on the outer surface of the bag. After a certain time, the gas passage area decreases and, consequently, the pressure drop in the fan increases.

This air blowing can be controlled electronically through a PLC programmed for automatic execution. Control is done by activating valves that allow compressed air, at a certain pressure, to enter the system through blowing tubes, which direct the air jet to each bag, creating the necessary agitation.

Efficient Particulate Handling & Large Gas Flow Filtration

Once shaken, the particulate material is detached from the surface of the bag and falls to the bottom of the hopper, where it is deposited for later transport. This transport of particulate material is taken into account at the time of design so that equipment can be designed with different hopper arrangements, which will identify the best type of output control for this material, whether by a screw conveyor in the case of longitudinal hoppers, rotary valves in the case of pyramidal hoppers, pneumatic conveyors or other technologies.

Different and standardized types of inlets influenced the type of deflector plate for internal protection of the bags and other internal components dimensioned so as not to cause a large loss of pressure in the system. For internal safety and maintenance, dampers are used, when required, to control the gas flow in each chamber.

CRANFOS’ extensive technology provides greater freedom to design filters for large gas flows without compromising efficiency or causing structural problems in our equipment. In special cases, CFD simulations are carried out to provide a preview of the system in operation.

For more information, please consult our Process Engineering team.

Some of Our Clients

We proudly partner with leading industries committed to environmental responsibility, delivering tailored solutions that help reduce emissions and meet regulatory standards. Our clients trust us to provide expertise and innovation, supporting their journey towards cleaner, more sustainable operations.