Advanced Industrial Equipment for Superior Environmental Control

Our Equipment

Advanced technology and versatile solutions. CRANFOS designs equipment to enhance air quality, safeguard health, boost productivity, ensure compliance, and reduce pollution control costs across diverse environmental projects.

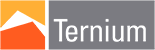

Bai-Press10® Bag Filter

With cutting-edge technology exclusive to CRANFOS, this equipment performs dry filtration of industrial gases and its name also comes from the type of cleaning to which it is subjected.

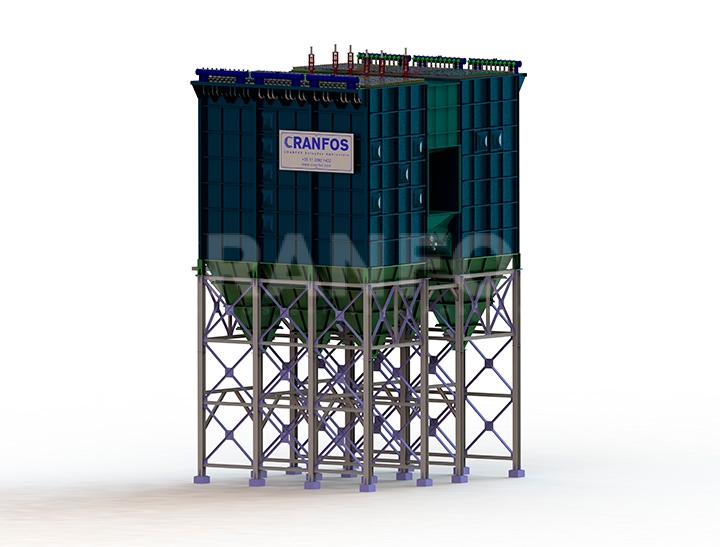

Conventional Bag Filter (High Pressure)

The conventional bag filter (high pressure) is used to filter various particulate materials from industrial process gases, whose forced flow through exhaust provides a continuous gas filtration operation through the bags.

Dry Electrostatic Precipitator

Although many say that this is a new technology, this equipment was already known in the 1920s. However, cutting-edge technologies have enabled CRANFOS to design and build equipment with levels of efficiency and versatility never seen before.

Wet Electrostatic Precipitator

Wet electrostatic precipitators are designed to eliminate liquid contaminants such as aerosols, sulfuric acid clouds (resulting from gas washing operations with SO3 in their composition) and dust particles in general.

Dampers

Dampers are applied to ducts with different dimensions and geometries, and meet small to large-scale applications with unique operational characteristics such as high temperatures, high particulate contents and different corrosive gases.

Desulphurization – Dry System

The dry desulphurization process, based on the circulating fluidized bed (CFB) principle, operates at a temperature of approximately 75/85°C, typically using hydrated lime for the combined absorption of SO2, SO3, HF and HCl.

Spare Parts

CRANFOS, through its Services and Assembly division, is able to supply parts and pieces for electrostatic precipitators and bag filters, according to the customer’s specifications and design.

Heat Exchangers – BOTFAN™

The air-to-air or air-to-gas heat exchanger can be installed to provide adequate conditioning of the gas coming from the process through the concept of forced convection.

Denitrification

CRANFOS also provides equipment for Denitrification, which acts by removing oxygenated nutrients connected to nitrogen and then returning it to the atmosphere in gaseous form.

De-sparking

Essential in many systems and processes, the spark arrester works with high performance in order to extinguish burning particles that come from the customer’s processes.

Multicyclone

With the same concept as a cyclone, this equipment is manufactured with several mini-cyclones coupled inside and which have the same role as a cyclone by centrifuging the gas and directing the particulate material to the bottom of the equipment for later removal or transportation.

Cyclones

Through the use of the concept of centrifugal movements, CRANFOS cyclones aim to separate gas from the particulate matter present in it.

Why Choose Cranfos?

At Cranfos, we go above and beyond what is expected of us. Here’s why companies rely on us for our outstanding dependability and quality:

100% Satisfaction Guarantee

Dedicated Support

Expertise That Drives Results

Companies we serve

We proudly partner with leading industries committed to environmental responsibility, delivering tailored solutions that help reduce emissions and meet regulatory standards. Our clients trust us to provide expertise and innovation, supporting their journey towards cleaner, more sustainable operations.